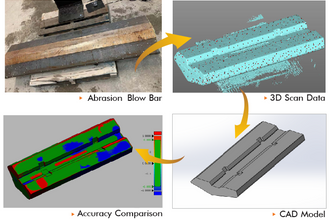

The heavy-duty machines use in the first mechanical stage of comminution are mainly jaw crushers. The pivoted jaw swings around the pivot and makes an impact on the fixed jaw, crushing the fed lumps in the jaw crusher. In order to decrease the replacement cost, choose the right material for your jaw crusher is the first thing.

BDI offers more jaw crusher plate styles than any manufacturer in the industry. Each of these designs has been developed for a customer seeking improved jaw crusher performance. We have many case histories in which wear life increase of 50% are common, and some in which wear life increased up to 200%. If you need a replacement jaw for your crushing machine that can withstand the toughest conditions, then you need BDI’s manganese jaws. Our replacement jaw feature in three grades depending on the crushing conditions encountered 13%MN, 18%MN, 21%MN. BDI’s replacement jaws offer to wear life and fit and go through a rigorous quality control process.

Benefit:

• Proprietary alloys offer increased toughness and durability.

• Better fit for quick and easy replacement

• Design improvement increases crusher efficiency and prevents premature erosion.

• Tested for longest usable wear life.

• A large inventory of crushers wears parts in stock for immediate deliveries.

• Less downtime for cost-saving.