Optimizing Equipment Performance: BDI Wear Parts' Titanium Carbide (TiC) Insert Bars Provide Long-Lasting Solutions for North American Customers

In North America’s mining, quarrying, construction, and cement industries, equipment durability and efficient operation are critical. Frequent equipment replacement or maintenance can cause significant downtime, severely impacting productivity and cost control. To help our North American customers tackle these challenges, BDI Wear Parts has introduced high-performance Titanium Carbide (TiC) insert bars, designed to enhance equipment performance and extend its service life.

Why Choose Titanium Carbide (TiC) Insert Bars?

-

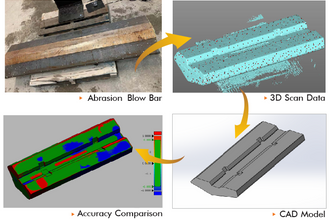

Superior Wear Resistance, Reduced Downtime

TiC insert bars significantly enhance the wear resistance of equipment, minimizing wear and tear. Whether used in crusher blow bars, bowl liners or jaw crusher liner, TiC technology can extend the service life of components several times over, drastically reducing downtime. -

Stringent Manufacturing Process, Ensuring Superior Quality

BDI Wear Parts’ manufacturing process involves several critical steps to ensure the high strength and durability of our products: - Heat Treatment: All parts undergo high-temperature heat treatment to further enhance material hardness and impact resistance.

- Hardness Testing: Each batch of products undergoes rigorous hardness testing to ensure they can withstand the most demanding conditions.

- Impact Testing: To guarantee durability in harsh environments, we conduct impact testing on components to ensure they can handle high-stress operations.

- Non-Destructive Testing (NDT): We use NDT to ensure that each component is defect-free during the production process, providing unparalleled quality assurance.

-

Why is the North American Market Ideal for This Product?

The industry structure in North America, coupled with the demand for high-strength equipment, especially in mining, construction, and heavy industries, makes durable, long-lasting equipment components highly sought after. BDI Wear Parts’ Titanium Carbide (TiC) insert bars are specifically designed for high-wear, high-impact working conditions and can withstand prolonged periods of high-intensity operations. - High Industry Standards: The industrial standards in the North American market are stringent, and equipment often operates under harsh conditions. Our TiC insert products have undergone rigorous testing and validation, fully meeting or even exceeding North American industry standards, helping customers maintain efficient operations.

- Reduced Equipment Downtime and Maintenance Costs: In the North American market, downtime can be extremely costly. Using our durable TiC insert bars can reduce the frequency of equipment replacements and maintenance, significantly lowering overall costs and increasing operational efficiency.

- Support for Sustainable Development: As the demand for sustainability increases in the North American market, extending the life of equipment components is an important means of reducing waste and improving resource efficiency. Our products help customers achieve higher sustainability goals by extending equipment life.

-

Cost-Effective Solutions

By reducing frequent equipment replacements, our customers save significant maintenance costs and time over long-term operations, further enhancing overall economic efficiency. BDI Wear Parts is committed to providing cost-effective solutions for our North American customers. -

Custom Designs to Meet Diverse Needs

Whether you are in mining, construction, or other high-wear industries, our TiC insert products can be customized according to your equipment specifications to ensure optimal performance.

About BDI Wear Parts

As a leading supplier of wear parts, BDI Wear Parts is committed to providing innovative solutions for our North American customers. Through advanced Titanium Carbide (TiC) insert technology, we help customers improve equipment performance, extend equipment life, and reduce operating costs. If you are looking for durable parts capable of handling high-wear, heavy-duty applications, contact us to learn how we can help take your business to the next level.