JOMA 6000 vs. Tungsten Carbide Snow Plow Blades

In harsh winter conditions, choosing the right snow plow cutting edge is essential to ensure efficient snow removal and reduce equipment wear. At BDI Wear Parts, we offer industry-leading cutting-edge solutions, including the JOMA 6000 and tungsten carbide snow plow blades. This blog will dive into the features of these two cutting edges and explain how BDI Wear Parts provides unmatched quality, fast delivery, and cost-effective solutions.

1. JOMA 6000 Snow Plow Blades: Superior Performance and Durability

The JOMA 6000 is a revolutionary product in the snow plowing industry, known for its unique design that enhances performance while minimizing road damage. The blade is composed of tungsten carbide inserts embedded in steel segments and encased in a rubber shell. This advanced structure offers several key advantages:

-

Noise and Vibration Reduction: Thanks to the rubber casing, JOMA 6000 blades drastically reduce vibration and noise during snow removal. This feature provides a smoother operating experience, lessens operator fatigue, and extends the lifespan of both the blade and equipment.

-

Longer Service Life: The tungsten carbide inserts are among the hardest materials available, offering excellent wear resistance. This means the JOMA 6000 can handle tough conditions while maintaining its cutting edge over time, reducing the frequency of blade replacements.

-

Road Surface Protection: The sectional design allows JOMA 6000 blades to follow the contours of uneven surfaces, minimizing damage to the road during snow removal. This makes it ideal for municipal and highway applications where road preservation is crucial.

2. Tungsten Carbide Snow Plow Blades: The Reliable Choice for Tough Conditions

Tungsten carbide snow plow blades are a more traditional yet highly effective solution for snow removal. They feature a long carbide insert brazed into a hardened steel blade, delivering high durability and excellent performance even in the most extreme conditions.

-

Extreme Durability: Tungsten carbide is renowned for its hardness and abrasion resistance, making these blades ideal for heavy-duty plowing. They are particularly effective for long stretches of highway or under severe winter conditions.

-

Cost-Effective Performance: While the initial investment may be higher than standard steel blades, the longer lifespan and reduced maintenance costs make tungsten carbide blades a cost-effective choice for operators seeking to minimize downtime.

-

Simple Design, Strong Results: These blades are easy to install and work well across different types of snow removal equipment, including front, underbody, and wing plows.

3. BDI Wear Parts: High Quality, Fast Delivery, and Unbeatable Value

At BDI Wear Parts, we are committed to providing cutting-edge snow plow solutions that meet your operational needs. Here’s why BDI Wear Parts is the right partner for your snow removal requirements:

-

Premium Quality: All of our products undergo rigorous testing and quality checks to ensure they meet the highest industry standards. From the superior materials used in the JOMA 6000 to the reliability of our tungsten carbide blades, you can count on BDI Wear Parts for exceptional performance.

-

Fast and Reliable Delivery: We understand that downtime can be costly, especially during the winter months. That’s why BDI Wear Parts has partnered with a trusted logistics team to ensure fast and reliable delivery to our customers, no matter where they are located.

-

Competitive Pricing: Our blades not only offer extended durability and superior performance but also come at competitive prices. This makes BDI Wear Parts the go-to choice for businesses looking to optimize their operational efficiency while keeping costs in check.

4. Why Choose BDI Wear Parts?

Whether you're in need of the noise-reducing and road-protecting JOMA 6000 or the durable, reliable tungsten carbide blades, BDI Wear Parts has the solution for you. We offer customized products to meet the specific needs of your snow removal equipment, ensuring optimal performance and longevity.

Related News

In harsh winter conditions, choosing the right snow plow cutting edge is essential to ensure effi...

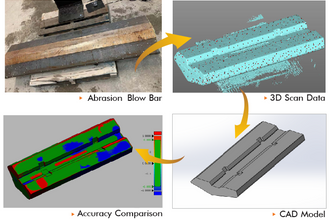

In North America’s mining, quarrying, construction, and cement industries, equipment durability a...

In the mining and construction industries, one of the most critical components in crushin...

In the ever-evolving world of wear parts and industrial equipment, staying ahead of the curve mea...

Wear Parts Materials in PropertiesManganese

Standard all-around manganese level and the most comm...

The heavy-duty machines use in the first mechanical stage of comminution are mainly jaw crushers....