News

- Home

- News

JOMA 6000 vs. Tungsten Carbide Snow Plow Blades

Ning Ma

In harsh winter conditions, choosing the right snow plow cutting edge is essential to ensure efficient snow removal and reduce equipment wear. At BDI Wear Parts, we offer industry-leading cutting-e...

Read More

Optimizing Equipment Performance: BDI Wear Parts' Titanium Carbide (TiC) Insert Bars Provide Long-Lasting Solutions for North American Customers

Ning Ma

In North America’s mining, quarrying, construction, and cement industries, equipment durability and efficient operation are critical. Frequent equipment replacement or maintenance can cause signifi...

Read More

Comprehensive analysis of ceramic insert blow bar: performance advantages and unique features of the BDI

BDI Wear Parts

In the mining and construction industries, one of the most critical components in crushing equipment is the blow bar. Recently, ceramic insert blow bars have gained popularity due to their superior wear resistance and durability. This article will explain what ceramic insert blow bars are, how they differ from traditional blow bars, what makes a good ceramic insert blow bar, and why BDI's ceramic insert blow bars stand out with their competitive pricing and faster delivery times.

Read More

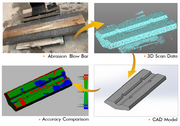

Revolutionizing Product Quality Control with Advanced Scanning Technology

BDI Wear Parts

In the ever-evolving world of wear parts and industrial equipment, staying ahead of the curve means embracing innovation. At BDI Wear Parts, we are excited to introduce a groundbreaking technology ...

Read More