Jaw Liner Maintenance: When and Why It Matters

Knowing when to change a jaw liner is crucial for maintaining optimal crusher performance and minimizing downtime. Here are some key considerations to keep in mind:

-

When to Change a Jaw Liner:

- It's time to change or rotate a jaw liner when there is less than 20% life remaining anywhere along the working face of the liner.

- Keep in mind that swing and fixed jaw liners wear at different rates. Typically, the ratio is 2 fixed jaw liners for every 3 swing jaw liners, though this may vary depending on the application.

-

Why Change a Jaw Liner?

- Excessively worn jaw liners can add stress to the crusher frames and bearings, compromising overall durability.

- Thin, worn jaw liners are prone to cracking, potentially damaging the crusher body and leading to costly repairs and extended downtime.

- Worn jaw liners directly impact production efficiency and can increase power consumption, affecting operational costs.

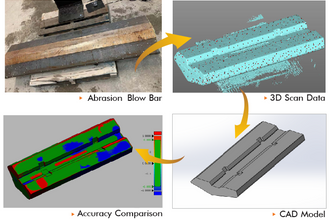

Figure 1: The Importance of Liner Profile

- In the accompanying diagram (Figure 1), 'H' represents the tooth height of a new liner, while 20% of 'H' serves as an indicator for when to rotate the jaw liner. This visual guide helps operators gauge the condition of the liner and take timely action to maintain optimal crusher performance.

Regular inspection and proactive maintenance are essential for extending the lifespan of jaw liners and maximizing crusher efficiency. By adhering to recommended replacement intervals and monitoring wear patterns, operators can minimize downtime, reduce repair costs, and ensure consistent production output.