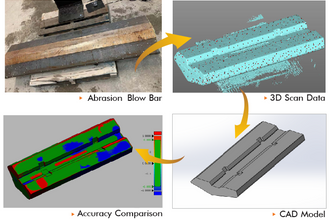

At BDI Wear Parts, our mission is clear: to craft longer-lasting blow bars for impact crushers, ultimately aiding our customers in reducing operational costs. We take pride in manufacturing a diverse range of blow bars tailored to fit multiple brands of impact crushers. With various materials available, we cater to different applications and conditions, aiming to significantly reduce crushing expenses for our customers.

Our lineup includes blow bars crafted from:

- Manganese steel

- Martensitic steel

- Martensitic steel with ceramic inserts

- Chrome white iron

- Chrome with ceramic inserts

Of particular note are our blow bars featuring ceramic inserts, boasting a remarkable increase in wear life of up to 100%.

High-Strength Construction Constructed from high-strength quenched and tempered steel, BDI blow bars exhibit three times the strength of carbon steel alone. This exceptional strength translates to enhanced performance and durability, ensuring our wear parts deliver optimal results. Depending on factors such as material type, feed size, abrasion levels, and presence of foreign elements, we offer additional options including manganese steel, Titanium Carbide (TiC), and CRA Ceramic, as well as high chromium white iron to suit diverse applications.

Martensitic Steel/Ceramic Blend Our Martensitic Steel/Ceramic composite blow bars feature hard ceramic particles embedded within a martensitic steel matrix. This unique composition combines the extreme hardness of ceramics with the mechanical properties of steel, resulting in blow bars that offer two to four times the lifespan of standard mono-alloy blow bars. With a steel hardness ranging from 44-57HRC and an impact strength of 100-300 J/cm3, these blow bars ensure exceptional performance and longevity.

Features & Benefits

- Superior design: Our HSI blow bars boast 3x-6x longer wear life, leading to significant cost savings for our customers.

- Rotational flexibility: Engineers can rotate the bar up to three times, maximizing its usable lifespan.

- Material versatility: Available in a range of material options including high-strength alloys, manganese, titanium carbide, and ZTA (Zirconia Toughened Alumina) ceramic, our blow bars can be customized to suit specific application requirements.

By investing in BDI Wear Parts' extended life blow bars, customers can achieve greater efficiency, reduced downtime, and ultimately, improved profitability in their crushing operations.